What Is an AC Condenser Unit? A Cross-Industry Power Player Explained

Let’s cut straight to the point. An AC condenser unit is the boxy, fan-equipped component you see outside homes, restaurants, factories, and server farms. It’s the heart of the heat rejection process in a standard split-system air conditioner or heat pump. In simple terms, the indoor unit absorbs heat from your building, and the refrigerant carries that heat outdoors to the condenser. Here, the refrigerant releases its captured heat into the outside air with the help of a coil and a fan, condensing from a hot gas back into a liquid before cycling back inside to repeat the job. Its performance directly dictates system efficiency, cooling capacity, and operational costs.

For you as a B2B distributor or importer, understanding the condenser unit’s nuances across applications is key to selecting the right inventory and advising your clients effectively. It’s far from a one-size-fits-all component.

H2: Commercial & Hospitality: Where Reliability Meets Aesthetics

In commercial spaces, condenser units are workhorses under constant pressure. A restaurant’s kitchen, a hotel’s guest wing, and a retail store have vastly different load profiles, but the demand for uninterrupted operation is universal. The conversation here shifts from basic cooling to strategic asset management.

We’re seeing a decisive move toward inverter-driven scroll compressors in commercial condensers. Unlike fixed-speed compressors that just turn on and off, inverter units modulate their speed to match the building’s exact cooling demand in real-time. The data is compelling: inverter systems can reduce seasonal energy consumption by 25-40% compared to conventional on/off units. For a hotel chain or a franchise restaurant owner, this isn’t just an equipment choice; it’s a direct reduction in operational overhead.

Noise level is a critical spec sheet number for urban installations. Units are now engineered with low-sound fan blades, insulated compressor compartments, and variable speed fans to keep decibel levels down, which is crucial for hotels or offices near residential areas. Aesthetically, there’s growing demand for slim-line, low-profile designs and even decorative grilles or wraps that allow the unit to blend into architectural designs, a significant selling point for high-end hospitality projects.

Durability is non-negotiable. Coastal distributors should prioritize units with anti-corrosion treatments, like epoxy-coated coils and galvanized steel cabinets. For Middle Eastern markets, units with high ambient temperature operation capabilities (able to function efficiently at 52°C/125°F and above) are a must-stock item.

H2: Agricultural & Process Cooling: Beyond Human Comfort

Here, the AC condenser unit sheds its comfort-label and becomes a precision tool for preservation and production. It’s about controlling environments for perishables and processes.

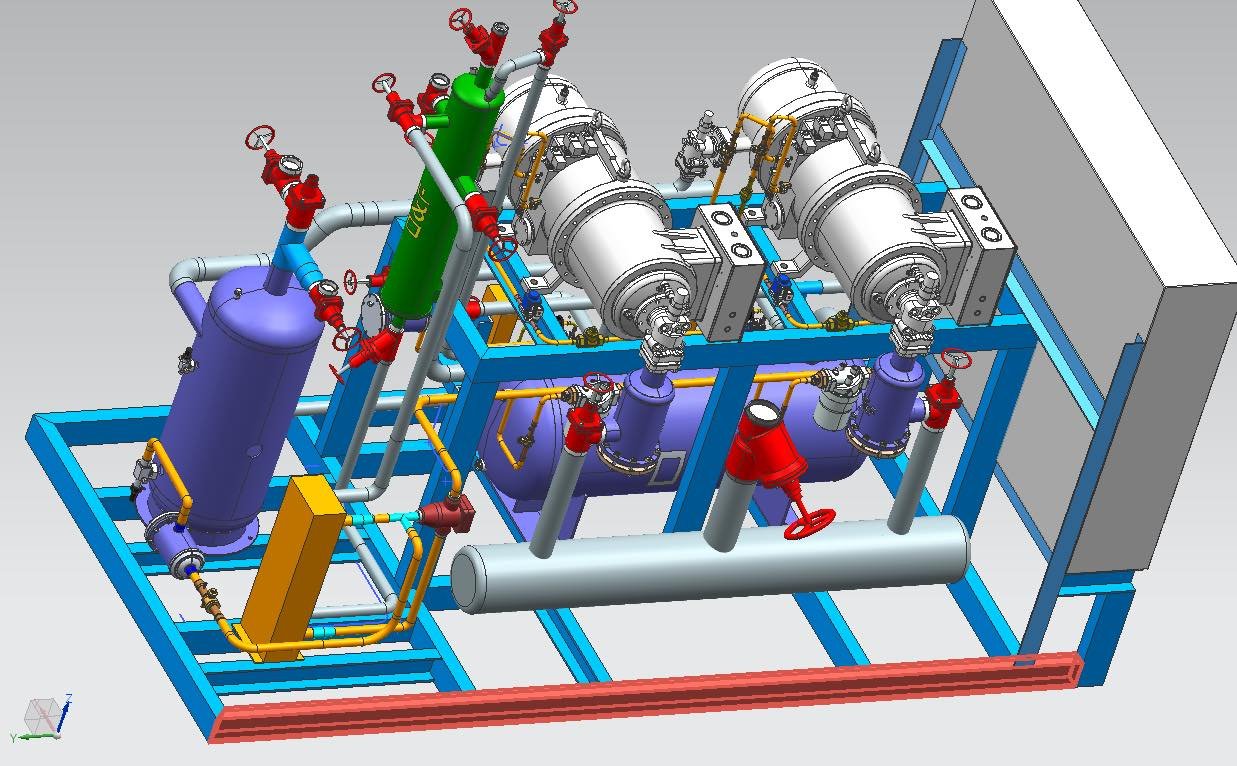

In cold storage logistics and farm produce packing houses, condenser units are part of larger refrigeration racks. The focus is on robust construction, easy serviceability, and stable performance in dusty or high-humidity environments. Copeland Scroll™ or Bitzer piston compressors are industry staples for their reliability under heavy loads. Distributors should note the rising integration of condensing units (condenser + compressor assembly) that are pre-charged and tested, simplifying field installation for contractors.

For hydroponics and controlled environment agriculture (CEA), precision is everything. Condensers work in tandem with humidity and CO2 controls. The latest trend is the use of condenser units with integrated heat recovery. The waste heat from the condensation process isn’t just ejected; it’s reclaimed to warm greenhouses during cooler periods, drastically improving the overall energy footprint of the facility. This is a powerful value proposition for progressive agri-business clients.

The pharmaceutical and certain food processing industries require Glycol Condensers. Instead of air, these units use a glycol-water solution to reject heat, allowing for precise low-temperature control critical for manufacturing processes. This represents a specialized, high-value niche in the B2B equipment market.

H2: Industrial & Data Center Applications: The Heavy-Duty Frontier

This is the high-stakes arena. Failure is not an option, and efficiency translates to massive financial implications.

Modern data centers, the backbone of the digital economy, generate immense heat. The condenser units here are part of Computer Room Air Conditioning (CRAC) or Chilled Water Systems. The current procurement focus is on variable capacity condensers with EC (electronically commutated) fans. EC fans offer superior efficiency, precise airflow control, and reduced power consumption compared to traditional AC fans. For a hyperscale data center, a few percentage points of improved condenser efficiency can mean millions saved in annual energy costs and water usage (in hybrid or adiabatic systems).

Redundancy is key. N+1 or 2N redundancy configurations mean multiple condenser units are installed so the system can withstand a unit failure without impacting critical operations. As a distributor, offering units designed for easy paralleling and system integration is crucial.

In general manufacturing plants, condensers face harsh conditions: airborne fibers, chemical fumes, and extreme particulate matter. Industrial-grade condensers feature heavy-duty louvered coils (often copper tube with aluminum fins for durability and cost-effectiveness), oversized filters, and corrosion-resistant coatings. The ability to perform in ambient temperatures up to 55°C is a standard requirement in many industrial zones. The drive towards Industry 4.0 means units with built-in connectivity for IoT monitoring (vibration, pressure, temperature, power draw) are moving from premium options to expected features, allowing for predictive maintenance.

| Table: Key Condenser Unit Specifications by Sector | Sector | Primary Compressor Tech | Critical Feature Focus | Trending Demand | Sample Real-World Spec |

|---|---|---|---|---|---|

| Commercial | Inverter Scroll | Noise Level, Aesthetic Design, Part-load Efficiency | Decorative Casings, IoT for Facility Mgmt. | Sound Power: <70 dB(A), IPX4 Weather Rating | |

| Agricultural | Robust Scroll/Piston | Dirty Environment Durability, Capacity Stability | Heat Recovery Integration, Plug-and-Play Units | Coil with Anti-Corrosion Coating, Hail Guards | |

| Industrial/Data Center | Scroll (often multiple) | Maximum Uptime, Extreme Ambient Performance, Connectivity | EC Fans, Redundant System Design, Free Cooling | Operation up to 55°C Ambient, MODBUS/BACnet Integration |

Professional Q&A for B2B Decision-Makers

Q1: For our clients in regions with high electricity costs, what’s the single most impactful condenser-related feature we should be promoting?

Without a doubt, inverter technology with a broad turndown ratio. A condenser with an inverter-driven compressor doesn’t just cycle on at 100% power and off. It can operate at 20%, 40%, 70% capacity as needed. This eliminates the massive inrush currents of start-stop cycling and matches output perfectly to the load, slashing energy waste. For a commercial building that rarely needs 100% cooling, the seasonal energy savings far outweigh the initial investment.

Q2: We get many questions about compatibility with existing systems. Is mixing condenser brands with indoor coils advisable?

It’s a technically complex question with a simple business answer: Strongly advise against it. While physically possible, mismatching components voids almost all manufacturer warranties and guarantees sub-optimal performance. Systems are designed, tested, and rated as matched sets (condenser + coil + metering device). A mismatch can lead to reduced efficiency, premature compressor failure, and tricky servicing issues. The business risk to your reputation as a technical advisor is high. Always recommend a fully matched system for new installations or a like-for-like brand replacement where possible.

Q3: What’s the real-world impact of the new environmental regulations (like the EU F-Gas phase-down) on condenser unit inventory and specifications?

This is critical for forward stock planning. Regulations are aggressively driving a transition from high-GWP (Global Warming Potential) refrigerants like R410A to lower-GWP alternatives like R32, and in some applications, R454B or R290 (propane). As an importer/distributor, you must:

- Check Destination Market Regulations: Know the legal phase-out schedules for your target countries.

- Source Future-Proofed Units: Prioritize manufacturers whose models are already designed and certified for R32 or other approved next-gen refrigerants. R32 units, for instance, often require slightly different compressor oils and safety switches.

- Educate Clients: Explain that while the upfront cost might be similar, investing in a next-gen refrigerant unit ensures longer-term compliance, avoids future retrofit costs, and often comes with efficiency improvements. Stocking obsolete refrigerant technology is a growing financial risk.