When Should You Bet Your Business on Danfoss Condensing Units? A Data-Driven Guide for Global Distributors

Let’s cut to the chase. You’re sourcing condensing units for your commercial, industrial, or retail clients worldwide. Your reputation hinges on reliability, efficiency, and total cost of ownership. The spec sheets all start to blur together, but one name keeps popping up with relentless consistency: Danfoss. Is it just legacy brand power, or is there a tangible, data-backed edge that makes their condensing units a smarter inventory choice for your business?

We’re not here to sell you on poetry. We’re here to look at the operational metrics, the cross-industry applications, and the real-world numbers that make Danfoss a recurring top-of-list recommendation for B2B distributors like you.

Commercial Refrigeration: The Backbone of Retail and Hospitality

Walk into any modern supermarket, convenience store, or restaurant chain. The silent hum in the background? That’s often a Danfoss condensing unit at work. The demand here is brutal: 24/7 operation, fluctuating door traffic, and zero tolerance for downtime that spoils inventory.

For your clients in this sector, the decision matrix focuses on two things: energy consumption and reliability. Danfoss units, particularly those equipped with variable speed drive (VSD) technology like in the Danfoss Turbocor TGS450 series, are engineered for this. Real-time data from large-scale retail installations show an average energy reduction of 30-40% compared to fixed-speed units in medium and low-temperature applications. For a distributor, this isn’t just a “green feature”; it’s your primary sales pitch for retrofits and new builds. Clients see a direct line from reduced kW/h to improved EBITDA.

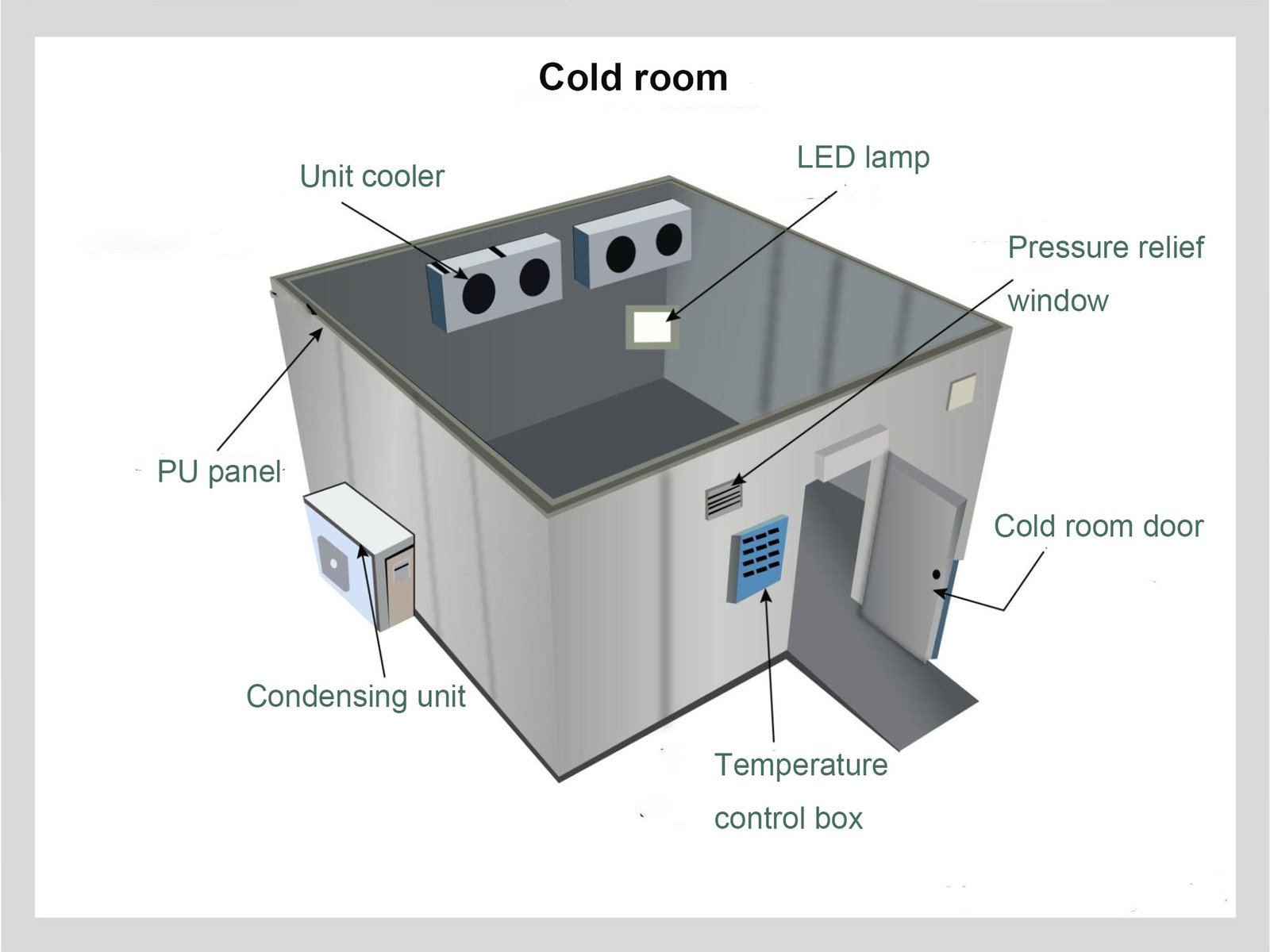

Then there’s modularity. The Danfoss MLM/MBM modular condenser series is a distributor’s dream for servicing the hospitality and small retail market. Need a unit for a walk-in cooler for a new hotel kitchen? A modular system allows for flexible configuration. This simplifies your inventory management—you stock core components that can be assembled to meet multiple custom orders, reducing lead times and increasing your responsiveness.

Industrial Process Cooling: Precision Where It Matters

This is where the stakes get high. We’re talking pharmaceuticals, chemical processing, plastics manufacturing, and data centers. Your clients here aren’t just cooling space; they’re cooling precise processes. A fluctuation of a few degrees can mean a ruined batch of vaccine, compromised server integrity, or inconsistent product quality.

Danfoss condensing units for industrial applications, such as those built around Danfoss industrial scroll compressors, are designed for extreme stability and scalability. They integrate seamlessly with sophisticated process control systems. The key metric here is COP (Coefficient of Performance) under varying loads. Recent performance logs from industrial plant installations highlight that Danfoss systems maintain a superior and stable COP across a 40-100% load range, thanks to advanced modulation technologies.

For you as a distributor, this translates into consultative selling. You’re not just moving boxes; you’re providing a critical component of a client’s production line. The data you bring to the table—mean time between failures (MTBF), maintenance interval projections, and compatibility with industry-standard PLCs—builds your credibility as a technical partner, not just a vendor.

Cold Chain Logistics: From Port to Pallet

The global cold chain is exploding, valued at over USD 300 billion in 2023 and projected to grow steadily. This is a golden opportunity for distributors. Whether it’s for refrigerated containers (reefers), transport refrigeration units (TRUs), or cold storage warehouses, the condensing unit is the heart of the system.

Danfoss has a formidable presence here, particularly with its Danfoss DST (Drive System Transport) and components designed for rugged, mobile use. The sales argument is built on durability and fuel efficiency (for transport) or total lifecycle cost (for warehouses). For reefers and TRUs, Danfoss’s optimized compressor and fan drive systems are proven to reduce fuel consumption by up to 15%, a massive cost saving for logistics fleets your clients supply.

In massive distribution warehouses, the integration of Danfoss condensing units with Danfoss ADAP-KOOL® controllers enables “smart cold storage.” This allows for zone-specific temperature management and predictive maintenance alerts. For a distributor, offering this ecosystem locks in client relationships. You become the single source for both the robust hardware and the intelligence that maximizes its value.

Side-by-Side: Key Danfoss Condensing Unit Series at a Glance

Here’s a snapshot of core product lines you should have in your catalog, based on 2024 specifications and market data.

| Product Series/Line | Best Suited For | Key Technology Highlight | Primary Value Proposition for Your Client |

|---|---|---|---|

| Danfoss Turbocor TGS/M | Large Commercial & Industrial Chillers | Magnetic Bearing, Oil-Free VSD Compressor | Ultra-high efficiency (IPLV up to 16), 50% less maintenance, 10-year compressor warranty. |

| Danfoss MLM/MBM Modular | Supermarkets, Convenience Stores, Hotels | Modular Design, Scroll Compressors | Flexible configuration, easy serviceability, reduced inventory complexity for you and the client. |

| Danfoss VZH Scroll Compressor Units | Industrial Process Cooling, Data Centers | High-Temp Scroll, Robust Design | Exceptional reliability at high condensation temperatures, stable COP for process stability. |

| Danfoss DST / TRU Components | Refrigerated Transport, Reefers | Compact, Vibration-Resistant Design | Fuel savings, extreme durability in mobile applications, global service network. |

| Danfoss Condensing Units with AK-SM 800 | Cold Storage Warehouses, Food Processing | Integrated with ADAP-KOOL® Controls | Smart system optimization, remote monitoring, predictive maintenance, energy savings. |

Your Top Questions, Answered with Current Market Context

Q1: With so many low-cost manufacturers entering the market, how do I justify the Danfoss premium to my price-sensitive clients?

A: Shift the conversation from upfront cost to Total Cost of Ownership (TCO). Present real data: A Danfoss VSD unit may cost 20% more upfront but can save 35% annually on energy. Over a 10-year lifespan, the energy savings often eclipse the initial equipment cost several times over. Additionally, factor in documented lower failure rates (check public MTBF comparisons) which reduce warranty claims for you and prevent costly downtime for your client. Your role is to be the financial and risk analyst for your client.

Q2: How strong is the global parts and service network? If I sell these in [Region X], will my clients be left waiting?

A: Danfoss’s logistics and partner network is one of its core strategic assets. As of 2024, they operate over 100 production facilities globally and have certified service partners in virtually every major market. For you, this means two things: 1) You can source products and replacement parts with reliable lead times, minimizing your capital tie-up in inventory. 2) Your clients have local technical support, which enhances their trust in your recommendation and protects your brand from post-sale service issues.

Q3: Are Danfoss units future-proof with evolving refrigerant regulations (like the EU F-Gas phase-down)?

A: This is a critical advantage. Danfoss designs its hardware to be refrigerant-agnostic. Their compressors, valves, and systems are extensively tested and approved for a wide range of low-GWP (Global Warming Potential) refrigerants like R-454B, R-290 (propane), R-600a (isobutane), and R-1234ze. By stocking Danfoss, you’re offering your clients a safe path through the regulatory maze. They can comply with today’s rules and transition to tomorrow’s refrigerants without replacing the entire unit, protecting their investment and your long-term relationship.

Q4: What’s the real margin potential for me as a distributor?

A: While unit margins are competitive, the real profitability lies in the recurring revenue stream and reduced operational hassle. High-reliability products mean fewer emergency calls, fewer warranty processing headaches, and more stable, predictable clients. Furthermore, selling a system (unit + controls + services) dramatically increases the average deal size. Your most successful peers aren’t just selling a condensing unit; they’re selling an energy-efficient, compliant, and intelligent cooling solution, with Danfoss as the reliable core. That’s where the margin and the loyalty are built.