Why Your Clients in Data Centers, EV Manufacturing, and Cold Chain Logistics Are All Asking About This One AC Component

Let’s cut right to the chase. If you’re a B2B distributor or procurement specialist sourcing HVAC systems, you’re not just moving boxes. You’re providing a critical component for operational continuity across industries. And the condenser unit is the linchpin. It’s not merely a “part” of an air conditioner; it’s the system’s primary heat expulsion engine. No effective condenser means no cooling, full stop. For your clients, from a factory floor manager to a data center CTO, that translates directly to downtime, product loss, and revenue hemorrhage.

The Core Physics: Rejecting Heat is the Real Job

Forget “making cold air.” An air conditioner’s job is to relocate heat. It grabs unwanted thermal energy from an indoor space and dumps it outside. The condenser unit’s role in this cycle is non-negotiable. Here’s the straightforward, unglamorous process: High-pressure, superheated refrigerant vapor from the compressor enters the condenser coils. As outdoor air is drawn over these coils (by the condenser fan), the refrigerant releases its latent heat. This causes it to condense—changing phase from a vapor to a high-pressure liquid. This liquid, now cooler but still under pressure, moves towards the expansion valve to start the cycle again. If this heat rejection phase is inefficient, the entire system’s capacity plummets, energy consumption soars, and equipment heads for premature failure. For your B2B customer, specifying a unit with a robust, well-designed condenser isn’t an upgrade; it’s a baseline for ROI.

Industry-Specific Demand: Where Condenser Performance Equals Profit

Generic cooling is a consumer game. In the B2B space, condenser specs are dictated by brutal operational realities.

Data Centers & Telecom Hubs: Here, heat density is the enemy. With rack power densities consistently rising, the condenser’s ability to reject massive heat loads 24/7 defines uptime. Modern facilities are moving towards condenser units designed for higher ambient temperature operation (like 55°C/131°F rated) and variable-speed drives that modulate precisely with server load. The latest trend you need to know? Integration with liquid cooling loops. The condenser is often the final heat rejector for these advanced systems, making its efficiency more critical than ever.

Electric Vehicle & Battery Manufacturing: Controlled environments are vital for battery cell formation, testing, and assembly. Even slight temperature deviations can impact quality and yield. Condenser units in these settings are part of precision HVAC systems that maintain ultra-strict humidity and temperature parameters. Reliability is purchased at a premium because a condenser failure could scrap a batch of high-value battery modules.

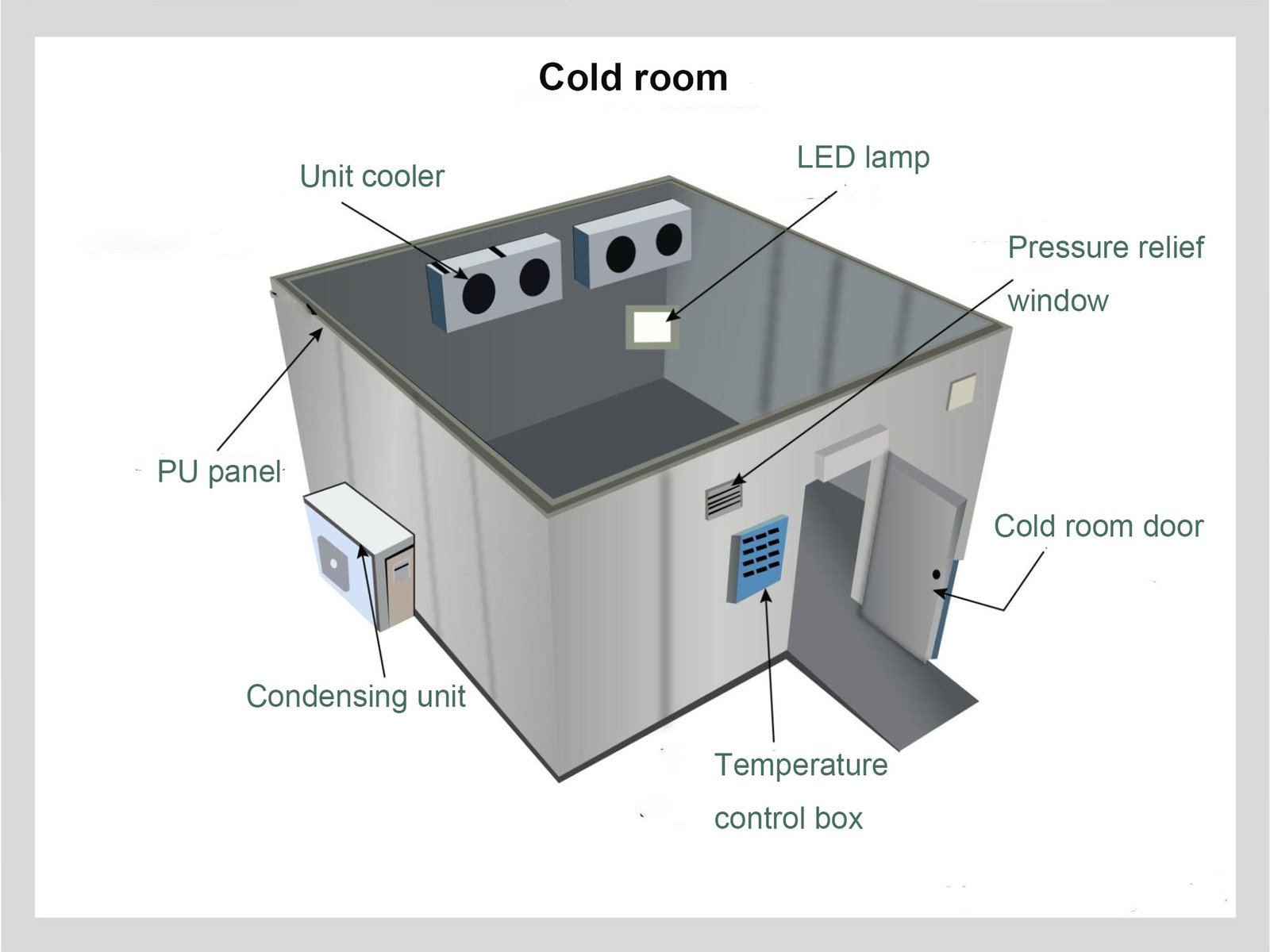

Pharmaceuticals & Cold Chain Logistics: This is about audit trails and compliance, not just cool air. Condensers for cold storage or climate-controlled warehouses must operate flawlessly across a range of external conditions to maintain unbroken temperature records. The focus for distributors is on units with corrosion-resistant coatings (for saline or chemical-laden atmospheres near ports) and compliant components that meet stringent industry regulations.

Specification Trends Impacting Your Inventory Decisions

The market is shifting fast. The condenser units that were standard five years ago are now often obsolete for commercial applications. Here’s what’s driving specifications now:

Regulatory Push for Lower-GWP Refrigerants: The global phasedown of HFCs (like R-410A) is real. New regulations, such as the EU F-Gas Regulation and similar actions worldwide, are pushing adoption of next-gen refrigerants like R-32, R-454B, and, in some applications, CO2 (R-744). Each refrigerant has different pressure and heat transfer characteristics. This means condenser coils, internal volume, and pressure ratings are being radically redesigned. You need to stock units compatible with the refrigerants your regional markets will demand tomorrow.

The Inverter & VRF Revolution: The move towards inverter-driven compressors and Variable Refrigerant Flow (VRF) systems is fundamentally changing condenser architecture. These systems modulate capacity based on demand. The condenser must be engineered to handle a wide range of refrigerant flow rates and pressures efficiently. For distributors, this means a growing SKU shift from fixed-capacity units to smart, communicating condensing units that are part of a broader system.

Resilience to Extreme Weather: With increasing frequency of heatwaves, condenser units must perform at peak load during extreme ambient temperatures. Look for specifications highlighting “High Ambient Performance” and designs that prevent head pressure shutdowns. This is a key selling point for clients in regions like the Middle East, South Asia, and even traditionally temperate zones now experiencing record highs.

Real-Time Market Data: The Distributor’s Lens

Understanding the technical shift is one thing; aligning your inventory with market growth is another. Here’s a snapshot of where demand is concentrated and expanding (Data sourced from industry reports, 2023-2024 projections).

| Industry Vertical | Key Condenser Demand Driver | Projected Growth Rate (CAGR, 2023-2028) | Critical Spec Focus for Distributors |

|---|---|---|---|

| Data Centers | Cloud expansion, AI server racks | ~12% | High-ambient capability, integration readiness |

| Commercial EV Charging Infrastructure | Thermal management of charging bays & battery buffering storage | ~25% | Robust construction, wide operating range |

| Biotech & Pharma Storage | Global vaccine logistics, personalized medicine | ~8% | Precision control, redundancy features |

| Food Processing & Retail Cold Chain | E-commerce grocery, supply chain modernization | ~7% | Hygienic design, energy efficiency (EEER) |

Navigating the Sourcing Conversation: Beyond Price per Unit

Your sophisticated B2B clients aren’t just buying a product; they’re investing in system reliability. Your value as a distributor increases when you guide the conversation beyond the price tag. Focus on lifecycle cost: a condenser with a more efficient coil design and a corrosion-protected cabinet might cost 15% more upfront but can save 30% in energy and prevent a catastrophic $50,000 downtime event two years down the line. Discuss serviceability: are the coil banks accessible for cleaning? Are standard industrial components used for fans and motors? This affects their maintenance overhead. Finally, verify compliance: can you provide documentation proving the unit meets the specific safety and performance standards (like AHRI, CE, or specific local codes) required for their project? This due diligence turns a transaction into a partnership.

Professional Q&A

Q: With the transition to A2L (mildly flammable) refrigerants like R-32, do condenser units require special modifications for safety?

A: Yes, absolutely. While the refrigerant itself is key, the system must be designed for it. Condensers for A2L refrigerants often incorporate specific electrical component ratings (spark-free or sealed where required) and may have altered internal volume to optimize pressure and flow. Always ensure the unit is certified and clearly marked for use with the specific refrigerant. Never retrofit an older R-410A unit for an A2L gas.

Q: For a client operating in a coastal region, what condenser features are non-negotiable?

A: Salt spray corrosion is a primary killer. Insist on units with a full, factory-applied anti-corrosion treatment. This goes beyond a standard paint job. Look for specifications like “Gold Fin” or “Blue Fin” coated copper tubes and aluminum fins, and cabinets made from galvanized steel or coated aluminum. Stainless steel hardware is a must. The initial investment prevents untimely failure and costly replacements.

Q: How significant is the fan motor technology in a condenser unit’s overall value proposition?

A: It’s critical. The fan is the workhorse of heat rejection. An ECM (Electronically Commutated Motor) or other variable-speed fan motor can adjust its speed based on head pressure, leading to significant energy savings (often 30%+ on fan power alone) and much quieter operation across varying loads. For clients focused on ESG goals or operating in noise-sensitive areas, this feature is a major differentiator against units with outdated fixed-speed PSC motors.