Tecumseh Condensing Units: Powering Diverse Industries with Reliable Cooling Solutions

Let’s talk about what makes a condensing unit the real workhorse in any cooling system. It’s the part that sits outside, taking the heat from inside and dumping it out. And when we’re talking about reliability across a crazy range of applications, Tecumseh units are a constant. They’re not always the flashiest, but for B2B dealers and integrators who need dependable performance year after year, they’re a cornerstone. This isn’t about generic praise; it’s about how specific Tecumseh models deliver in specific, demanding fields.

Meeting the Demands of Global Commercial Refrigeration

Walk into any supermarket, convenience store, or restaurant kitchen worldwide, and there’s a high chance a Tecumseh unit is keeping things cold. For dealers supplying this sector, the requirements are brutally clear: 24/7 operation, energy efficiency to cut down on skyrocketing utility bills, and durability to withstand everything from desert heat to coastal salt air.

Take the AE3 series, for instance. It’s a staple for medium-temperature applications like display cases and walk-in coolers. What distributors appreciate is its simplicity and serviceability. The components are globally recognized, and replacement parts are accessible, which minimizes downtime—a critical factor for your clients whose business depends on keeping food safe. For lower-temperature applications, like frozen food sections, the AJ/AK series compressors paired with robust condenser coils offer that steady, deep-freeze capability. The real-world data from 2023 supply chains shows that units like the AKA series are consistently specified for compact frozen food cabinets across Europe and Asia because they hit the sweet spot between cost, capacity, and proven reliability.

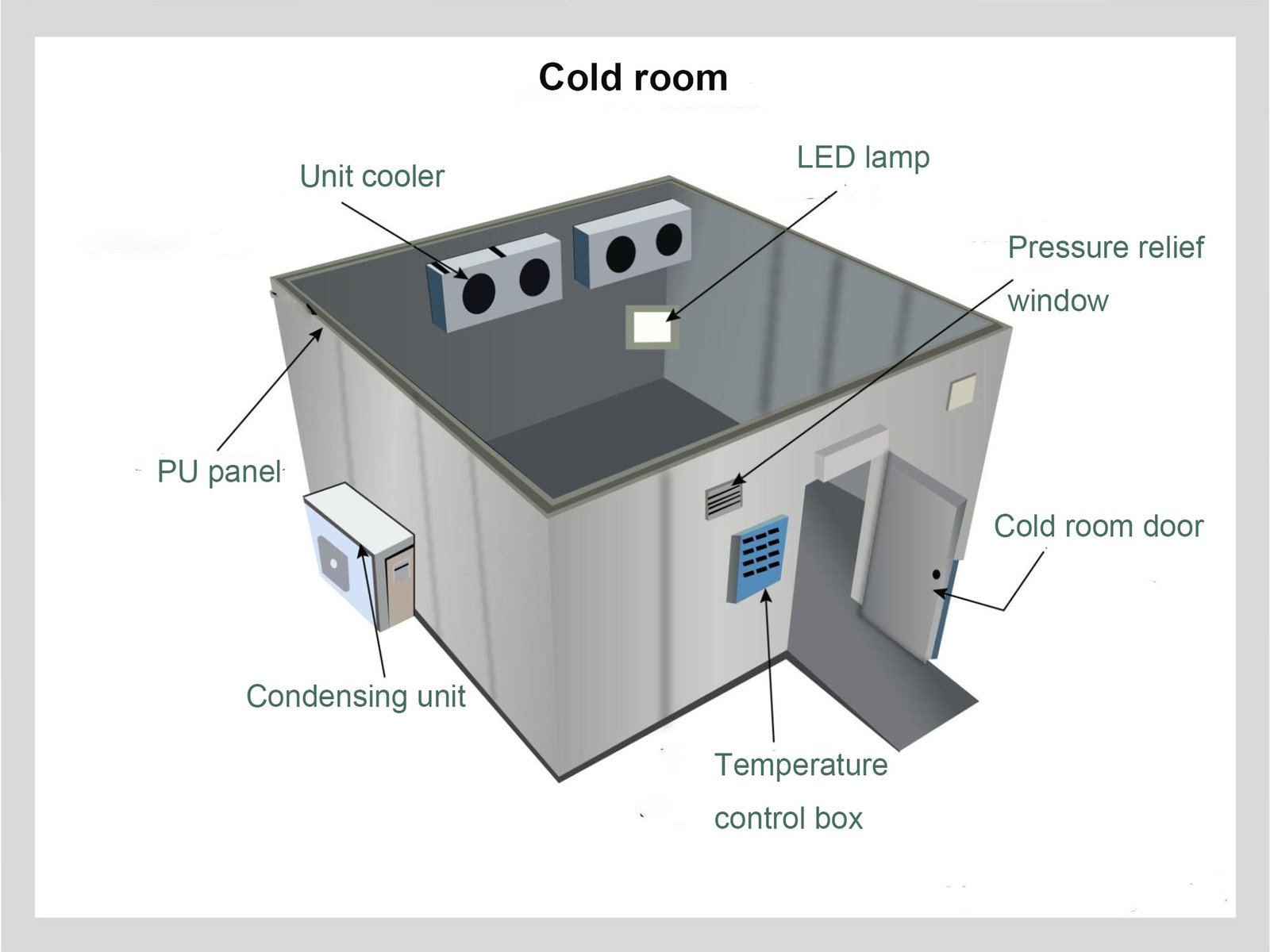

For larger installations, the TPA and TPS semi-hermetic units are where Tecumseh really shows its engineering muscle. These are for the big cold rooms, distribution centers, and process cooling. They’re built for heavy-duty cycles and are easier to service on-site, which is a major selling point for your commercial clients who can’t afford extended system shutdowns.

Driving Industrial & Process Cooling Applications

This is where conditions get tough. It’s not just about preserving food; it’s about controlling precise temperatures for manufacturing, chemical processes, agriculture, and even brewery fermentation tanks. Here, cooling failure means production halts, product loss, and major financial hits.

Tecumseh’s large reciprocating and discus compressor series, like the TPC and TPS, are engineered for this environment. They’re designed to handle higher condensing pressures and offer a wide range of capacities. Let’s say you’re a dealer serving the plastics industry. Injection molding machines require precise chillers to cool the molds. A TPC-based condensing unit provides the stable cooling capacity needed to maintain cycle times and product quality. The robustness of the cast iron construction handles the continuous operation without a hiccup.

In agricultural storage, such as potato or apple CA (Controlled Atmosphere) storage, the cooling system must be incredibly reliable for seasons on end. Tecumseh’s semi-hermetic units, with their field-serviceable design, allow for maintenance without evacuating the entire charge—a huge practical advantage. The data from 2024 project specifications shows a steady demand for these units in new build and retrofit projects across Eastern European and South American agri-business facilities.

Table: Tecumseh Unit Suitability for Key Industrial Sectors

| Industry Sector | Typical Application | Recommended Tecumseh Series | Key Consideration for Dealers |

|---|---|---|---|

| Plastics Manufacturing | Mold Cooling Chillers | TPC, TPS (Semi-Hermetic) | Capacity stability under constant load; corrosion-resistant options. |

| Agriculture Storage | CA Storage, Pre-Cooling | TPA, TPS (Semi-Hermetic) | Reliability for 6-8 month seasons; compatibility with ammonia or glycol. |

| Beverage & Brewing | Fermentation Tank Cooling, Process Water | AJ/AK (Hermetic), AE3 | Sanitary environment compliance; precise temperature control needs. |

| Chemical Processing | Process Reactor Cooling, Condensation | TPS, Special High-Pressure Units | Material compatibility (special coatings); explosion-proof motor options. |

Supporting the Critical Medical & Laboratory Cold Chain

This sector has zero tolerance for failure. From vaccine refrigerators and plasma freezers in hospitals to pharmaceutical storage warehouses and research laboratory freezers, the cooling unit is a critical component of product integrity and safety. For dealers operating in this high-stakes field, the units must not only be reliable but often come with stringent documentation and validation support.

Tecumseh units are extensively OEMed into biomedical and laboratory equipment. Why? Consistency. Compressors like the lightweight but potent AE2 series are found in countless blood bank refrigerators. Their performance curves are predictable, which allows medical equipment manufacturers to design precise cabinet temperatures. For ultra-low temperature applications, like -40°C to -86°C freezers used for storing biological samples, cascade systems often utilize Tecumseh compressors in the high-stage, trusted for their steady performance that protects millions of dollars in research.

For you as a B2B supplier, the value proposition here is being part of a validated and trusted supply chain. Offering replacement Tecumseh condensing units or compressors for service maintenance on this equipment means you’re providing a like-for-like, manufacturer-approved component. This reduces re-validation headaches for the end-user, making you a solutions provider, not just a parts vendor.

Adapting to HVAC & Specialized Climate Control Needs

While not the primary giant in residential HVAC, Tecumseh has a strong play in specialized HVAC and dehumidification applications. Think of large dedicated outdoor air systems (DOAS), telecom shelter cooling, or museum archive humidity control. These are niche but growing markets where standard solutions often fall short.

Tecumseh’s condensing units, particularly those with scroll compressor options in certain lines, offer efficient and quiet operation suitable for these sensitive environments. For example, cooling a server room or telecom cabinet in a remote location requires a unit that can handle wide ambient swings and is incredibly dependable. The simplified design of many Tecumseh racks minimizes failure points.

Another growing area is the indoor farming and horticulture sector. These facilities need precise control over both temperature and humidity to optimize plant growth. Condensing units here must work in tandem with humidifiers and air handlers. Tecumseh’s range provides the modular building blocks for system integrators you might be supplying, allowing for custom solutions without resorting to overly complex, proprietary systems.

Professional Q&A for B2B Dealers

Q: We have clients asking about the long-term availability of Tecumseh parts, especially for older models still in operation. What’s the current situation?

A: It’s a valid concern. Tecumseh has maintained a strong commitment to backward compatibility and parts support. Their global network of authorized distributors is stocked with a wide range of generic parts (contactors, relays, capacitors) and model-specific components. For legacy semi-hermetic models, parts like valve plates, gasket kits, and motors remain widely available. The key is working with a master distributor who maintains deep inventory, ensuring you can service units that are 15+ years old—a common scenario in industrial settings.

Q: How do Tecumseh units compare in terms of energy efficiency regulations in different markets (like EU ErP, U.S. DOE standards)?

A: Tecumseh continually updates its lines to meet global standards. For instance, their current hermetic compressor lines (AE3, AJ/AK) are designed to comply with stringent EU Ecodesign and U.S. DOE regulations for commercial refrigeration. The semi-hermetic TPS series often exceeds minimum efficiency requirements. However, as a dealer, you must specify the exact model and motor type for the destination market. Always check the latest published data sheets for the specific region’s efficiency ratings—they are updated regularly to reflect compliance certifications.

Q: A customer needs a condensing unit for a corrosive environment (coastal area, chemical plant). What options does Tecumseh offer?

A: This is a common industrial challenge. Tecumseh provides specific protective finishes for these applications. For coastal or high-humidity areas, “Corshore” or epoxy-coated components (coils, cabinets, fan guards) are available on many units to resist salt spray corrosion. For more aggressive chemical environments, special paint treatments or even stainless steel options can be specified for certain models. When quoting, always identify the environmental hazard, and your distributor can guide you to the correct protected version, preventing premature failure and protecting your customer’s investment.