Cold room project in Uzbekistan, it is a fresh fruit plant, customer is a farmer, they harvest the fruit, such as apple, will store them 6 months, and then sell them to supermarket, 25% price higher.

Fruit cold room preparation

Cold room specification details.

· Pre-cool Room Dimension: 15m*5m*4m, room temp: +10℃, it can pre-cool the fruit from +34℃ to +10℃ in 24 hours, take the much heat away, to keep fruit can store for long time well in cold room.

· Chiller room is 15*25*8m, Temperature is +3℃, it can store 500 tons fruits.

Products we design for cold room in Uzbekistan

1. Cold room PU insulation panel specification.

| Core | Polyurethane(P.U.) Foam |

| Density | 40±2kg/m3 |

| Blowing Agent | Cyclo-Pentane |

| Skin: Corrugated type | Polyester Resin Coated G.S.(Galvanized steel) |

| Thermal Conductivity | 0.018k Cal/ m h ℃ |

| Effctive width: | Standard: 960mm |

| End connection | Tongue and groove/plain |

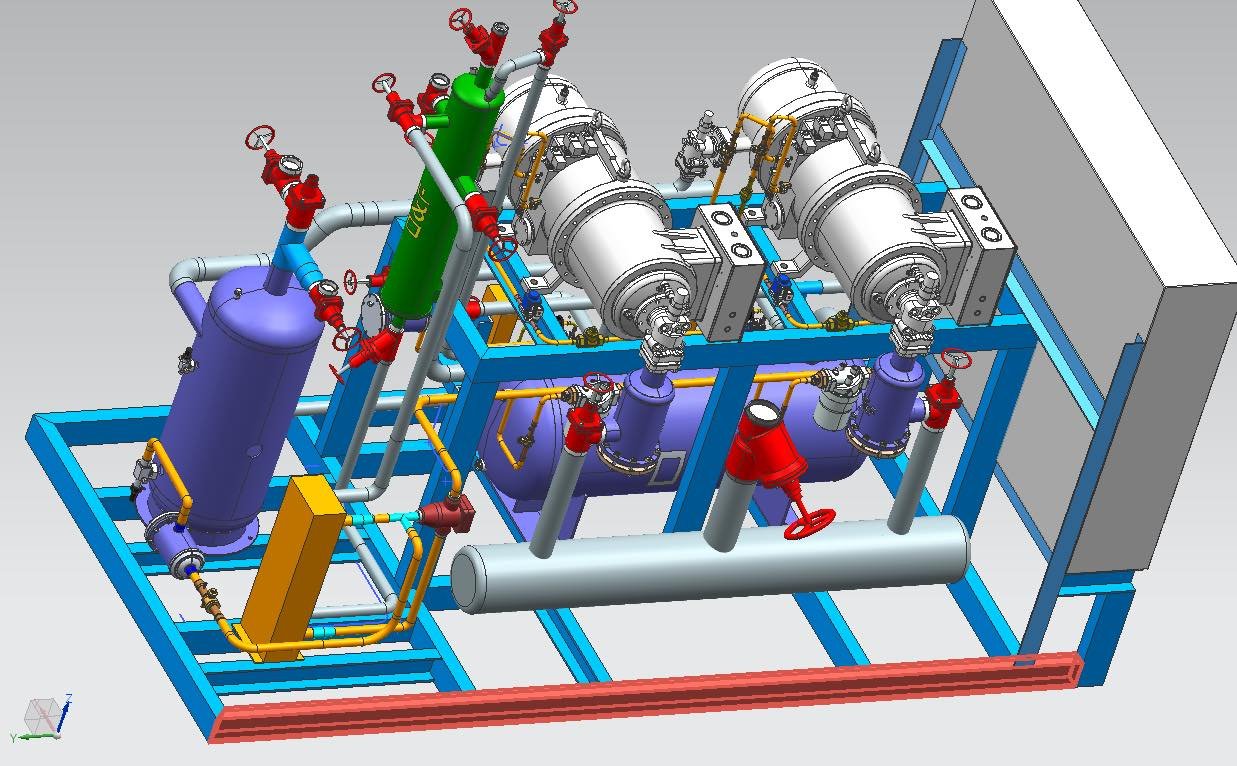

2. Refrigeration System

Consider position of project in Uzbekistan, hot ambient temperature, can reach +55℃ in summer, and low humidity,this situation make the fruit lose water soon, so there is high standard request for refrigeration system.

So we design it with Bitzer compressor, The reason is as following:

For more than 80 years, the BITZER name has represented the highest quality, efficiency and reliability. BITZER is the only company to produce all three primary types of compressor: reciprocating, screw and scroll. And with its environmentally friendly solutions and innovative electronic products, BITZER is driving the refrigeration and air-conditioning industry around the world.

Bitzer Condensing Unit is most important part in whole refrigeration system, it has Bitzer semi-hermetic compressor (Germany brand), crankcase heater, vibration absorber, oil separator, air cooled condenser, axial fan, liquid receiver, High and low pressure switch, high pressure gauge, low pressure gauge, sight glass, solenoid valve, dry filter, suction accumulator and electrical junction box.

Cold room Installation

1. Concrete Slab Design—The concrete slab must be designed to resist the punching shear and weight of the pallets racks.

2. Under Floor Insulation—Under floor insulation must provide sufficient compressive strength support the loads from the overlaying floor slab without crushing it. XPS is recommended since it provides a compressive strength of 45 PSI. The insulation should be placed directly below the freezer slab.

3. Cold room with PU panel installation

Learning the Operation of the Permanent Cam Lock System:

Before starting the assembly of the panels, make sure that the locking devices are at the stop position. To do so, turn the locking devices counter-clockwise, using a wrench, with force, until it stops moving any further.

Push panels together and turn wrench 1/4 turn clockwise. This will engage the male locking device “arm” over female locking device “pin”.

Keep turning the wrench for another _ of a turn until the wrench stops moving any further.If there are any problems during the operation of cam locks, turn the wrench counter-clockwise with force until it stops moving any further. This will put the locking device at its original position and you can try to assemble the panel again by moving the wrench in a clockwise direction.

4. Refrigeration system installation

It is the most important part in whole project, its installation can influence the efficiency of project, so our engineer discussed more with clients, so familiar with the site situation, issue the details installation layout.

Now the project has running 2 years, everything are great, keep well maintenance, it can support more for clients’ fruit business!