Your cooling distribution unit isn’t just a box in the corner — it’s the silent guardian of your critical operations. Whether you’re running a server farm, a surgical suite, or an automated production line, a hiccup in cooling can mean downtime, data loss, or compromised safety. Maintenance isn’t about fixing problems; it’s about preventing them entirely. Let’s break down the real-world, step-by-step upkeep that keeps your CDU running silently and efficiently, year after year.

Data Center & Server Room Specifics: Keeping the Digital Heartbeat Alive

In data centers, CDUs are mission-critical. A failure here doesn’t just mean an uncomfortable room; it can trigger server throttling and catastrophic shutdowns. The maintenance focus is on precision, redundancy, and cleanliness.

Start with the fluid. Check the coolant level and quality weekly. For water-based systems, monitor conductivity and inhibitor concentration monthly. A sudden change can signal corrosion or biological growth. Drain and replace the fluid annually, or as per your fluid manufacturer’s spec — don’t guess. Filter inspection is non-negotiable. Check inlet filters every two weeks in dusty environments. A clogged filter drops airflow, causing pumps to work harder and coils to ice over. Replace them on a strict schedule, not just when they look dirty.

The pump is the heart. Listen for unusual vibrations or cavitation sounds — a “gravelly” noise indicates trouble. Check pump seals for minor leaks and monitor motor amperage. A rising amp draw can point to bearing wear or impeller issues. Valves and connections need a quarterly tactile check. Feel for moisture, look for mineral buildup or slight weeping. Tighten connections to manufacturer torque specs; overtightening cracks fittings.

For the control system, log all temperature and pressure readings daily. The trend is your friend. A gradual rise in supply temperature at a constant load might mean fouled heat exchangers. Calibrate sensors annually. Dust the cabinet interiors and ensure fans are free of debris. Your CDU’s airflow is as important as its water flow.

Healthcare & Laboratory Applications: Where Precision Meets Safety

In hospitals and labs, CDUs cool MRI machines, CT scanners, and lab equipment. The stakes involve patient safety and research integrity. Maintenance here is governed by strict protocols, often tied to facility accreditation.

Fluid selection and handling are paramount. Use only approved, high-purity fluids. Any leakage into a clinical environment is a severe incident. Check for leaks daily. Perform a thorough integrity test on tubing and connections monthly. Fluid testing is frequent — test for microbial contamination weekly in sensitive areas. Use certified, particle-free filters and change them under sterile conditions when possible.

Noise and vibration are critical in patient areas. Conduct regular vibration analysis on pumps and compressors. Even a slight increase can disturb sensitive imaging equipment. Insulation on pipes must be intact and dry; wet insulation is a breeding ground for pathogens.

Documentation is part of the maintenance. Every check, test, and fluid change must be logged with time, date, and technician ID. This isn’t bureaucracy; it’s a traceability requirement. Calibration of all monitoring probes (temperature, flow, pressure) happens quarterly, against certified standards. The focus is on predictable, verifiable performance, not just fixing what breaks.

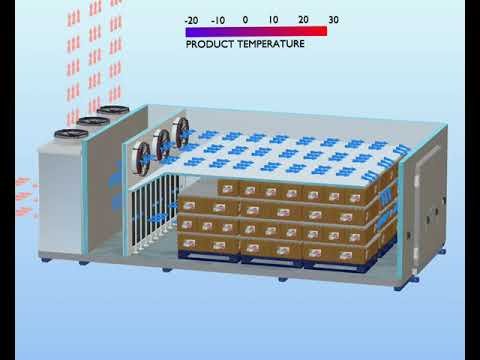

Industrial & Manufacturing Floor Upkeep: Durability Under Pressure

On the factory floor, CDUs cool laser cutters, plastic injection molds, and welding robots. The environment is harsh: airborne oils, metal particulates, and constant vibration. Maintenance is about ruggedness and preventing contamination.

The enemy is particulate matter. Air-cooled condensers and fans get coated quickly. Inspect and clean condenser coils with non-corrosive coil cleaner at least monthly. Consider installing protective screens, but clean them even more frequently. For the internal loop, use a robust, corrosion-inhibited fluid. Test fluid viscosity and pH monthly. Contaminants from the atmosphere can ingress, changing fluid chemistry.

Mechanical components take a beating. Check pipe supports and vibration isolators quarterly. Loose brackets from machine vibration can cause fatigue cracks. Inspect pumps for seal wear more often — every three months is wise. Keep spare pump seals and gaskets on hand to minimize downtime.

The control system needs to be “dumb-proof” and accessible. Protect electrical panels from dust and moisture. Check sensor accuracy often, as they can be coated or misaligned. Emphasize simple, clear daily operator checks: visual inspection for leaks, ensuring inlet/outlet grilles are unobstructed, and verifying alarm panels are active.

CDU Industry Application & Maintenance Focus Table

| Industry / Application | Primary Function | Critical Maintenance Focus | Real-Time Monitoring Priority | Common Failure Point to Watch |

|---|---|---|---|---|

| Data Center | Cooling server racks, networking gear | Coolant purity, pump health, filter changes | Delta T (ΔT) across racks, fluid flow rate | Clogged filters leading to pump cavitation |

| Healthcare (Imaging) | Cooling MRI, CT, LINAC systems | Vibration control, sterile fluid integrity, leak prevention | Cooling water temp & pressure to spec | Insulation damage causing condensation & microbial growth |

| Pharma / Lab | Precise temp control for processes & storage | Microbial contamination prevention, sensor calibration | Point-specific temperature stability | Degraded fluid inhibitors leading to corrosion |

| Industrial Lasers | Removing high heat loads from laser sources | Contamination control (particulates, oils), pump durability | Laser chiller outlet temperature | Clogged external heat exchanger fins from factory dust |

| Plastic Injection Molding | Precise mold temperature control | Scale/corrosion inhibition in water loops, valve operation | Mold in/out temperature consistency | Mineral scale buildup in mold flow channels |

Q: We see a slow but steady rise in system pressure drop over 6 months in our data center CDUs. Fluid is clean. What’s the most likely culprit?

A: This classic symptom typically points to microbial biofilm buildup or very fine particulate accumulation inside the plate heat exchanger or in smaller-diameter tubing. Even with clean-looking fluid, bacteria can form a slimy layer that dramatically reduces flow. A professional chemical flush and a review of your biocide treatment protocol are needed.

Q: In our factory, the CDU alarm keeps triggering for “Low Fluid Temperature,” but the equipment seems cooled fine. Should we ignore it?

A: Never ignore this. It often indicates a problem with the sensor or its placement, but it could also mean a malfunctioning modulating valve is allowing too much bypass, or the fluid flow rate is too high. First, calibrate or replace the sensor. If the problem persists, check valve operation and verify the flow rate matches the design specification for the current load.

Q: Our hospital’s CDU for the MRI suite is noisier than when installed. What’s the urgent check?

A: Immediate priority is vibration isolation. Check if pump or compressor mounts have loosened or degraded. Then, inspect fan blades and motors for imbalance or bearing wear. Also, ensure no ductwork or panels have come loose, creating resonance. Unusual noise in a clinical setting often precedes mechanical failure and can interfere with imaging quality.

Q: Can we switch to a different brand of coolant in our CDU to save costs?

A: This is a high-risk move. Fluids are not universally compatible. Mixing or changing types can cause chemical reactions, seal degradation, or loss of corrosion inhibition, leading to system-wide failure. Always consult your CDU and fluid manufacturer’s guidelines. Stick with approved fluids, and if a change is considered, a complete system flush and compatibility test by a professional is mandatory.