How to Keep Your Walk-In Cold Rooms Running Like a Swiss Watch (No Matter Your Industry)

Let’s cut to the chase. You’re not just selling a big refrigerator; you’re selling a critical asset for your clients’ businesses. Whether they’re storing gourmet cheese, life-saving vaccines, or the finest cuts of sashimi-grade tuna, a walk-in cold room failure isn’t an inconvenience—it’s a financial disaster. Your B2B buyers, the distributors and dealers, need to know you understand the gritty details that keep their end-users’ operations flawless. So, here are the actionable, no-fluff tips that prove your expertise and help them sell with confidence.

The Foundation: Mastering Temperature Integrity

Forget “cold enough.” It’s about precision and consistency. A one-degree fluctuation can mean spoiled product, violated safety regulations, and ruined inventory.

- Zone Defense is Key: Stop thinking of it as one big space. Map out temperature zones. The area right by the evaporator fan will be coldest, while corners furthest from airflow can be warmer. Use multiple, calibrated digital thermometers or data loggers to identify these zones. The current industry benchmark for high-performance cold rooms demands a max temperature variation of ±0.5°C (±0.9°F) throughout the entire space.

- Smart Monitoring is Non-Negotiable: Ditch the old dial thermometer. Recommend and integrate IoT-enabled monitoring systems that provide real-time, remote data to your client’s phone. Alerts for temperature excursions are sent instantly, not discovered hours later. This is a huge value-add you can offer. Data from 2023 shows that facilities using cloud-based monitoring reduce spoilage incidents by over 70%.

- The Door is the Weakest Link: It’s the most used and most abused part. Air curtains and strip curtains are not optional; they’re essential. A high-speed air curtain for high-traffic areas can reduce cold air loss by up to 80% compared to an open door. For dealers, stocking compatible, energy-efficient door solutions is a smart upsell.

Industry-Specific Demands: One Size Fits None

A cold room for a craft brewery is a different beast from one for a pharmaceutical lab. Your advice must reflect that.

- Food Service & Distribution: Here, it’s about volume and turnover. Focus on robust racking systems that allow for FIFO (First-In, First-Out) organization and easy cleaning. Emphasize flooring—seamless, coved, antimicrobial floors that can withstand daily power-washing are a must. Humidity control (around 85-95% for produce, 50-60% for meat) is crucial to prevent dehydration or mold.

- Healthcare & Pharmaceuticals: This is the pinnacle of precision. Compliance with standards like WHO-GDP or EU GMP is everything. Highlight your equipment’s capability for detailed, audit-ready temperature logging and alarm systems with battery backup. Stability is key—even during defrost cycles, the temperature must remain within strict limits (e.g., +2°C to +8°C for vaccines).

- Floral Industry: It’s not just cold; it’s dark and humid. Floral cold rooms need specialized lighting (often low-heat LED with specific spectra) and very high humidity levels (90-95%) to preserve freshness. Air circulation must be gentle to avoid dehydrating delicate petals.

- Laboratories & Research: Often requiring ultra-low temperatures (down to -40°C or lower). The focus is on compressor reliability, advanced insulation, and safety features like door releases from the inside. Redundant systems are a frequent request.

Proactive Maintenance: The Service Contract Lifesaver

This is where you build long-term partnership value. Teach your dealers to educate their end-users.

- The Coil Check: Evaporator and condenser coils must be clean. A layer of frost or dust acts like a blanket, forcing the compressor to work 30% harder, skyrocketing energy bills and shortening its life. Quarterly visual checks are mandatory.

- Gasket Integrity: That rubber seal around the door is a hero. Check it monthly for cracks, tears, or stiffness. A simple dollar bill test (close it on a bill; if it pulls out easily, it’s failing) can prevent massive energy waste.

- Defrost Discipline: Automatic defrost cycles must be scheduled during low-activity periods. Ensure drain lines are heated and clear to prevent ice blockages, which can lead to water damage and system shutdown.

Energy Efficiency: The Silent Salesman

For your B2B buyer, a cold room’s operating cost is a major selling point. Arm them with facts.

- Evaporator Fan Upgrades: Modern ECM (Electronically Commutated Motor) fans can adjust speed based on demand, using up to 70% less energy than standard shaded-pole motors.

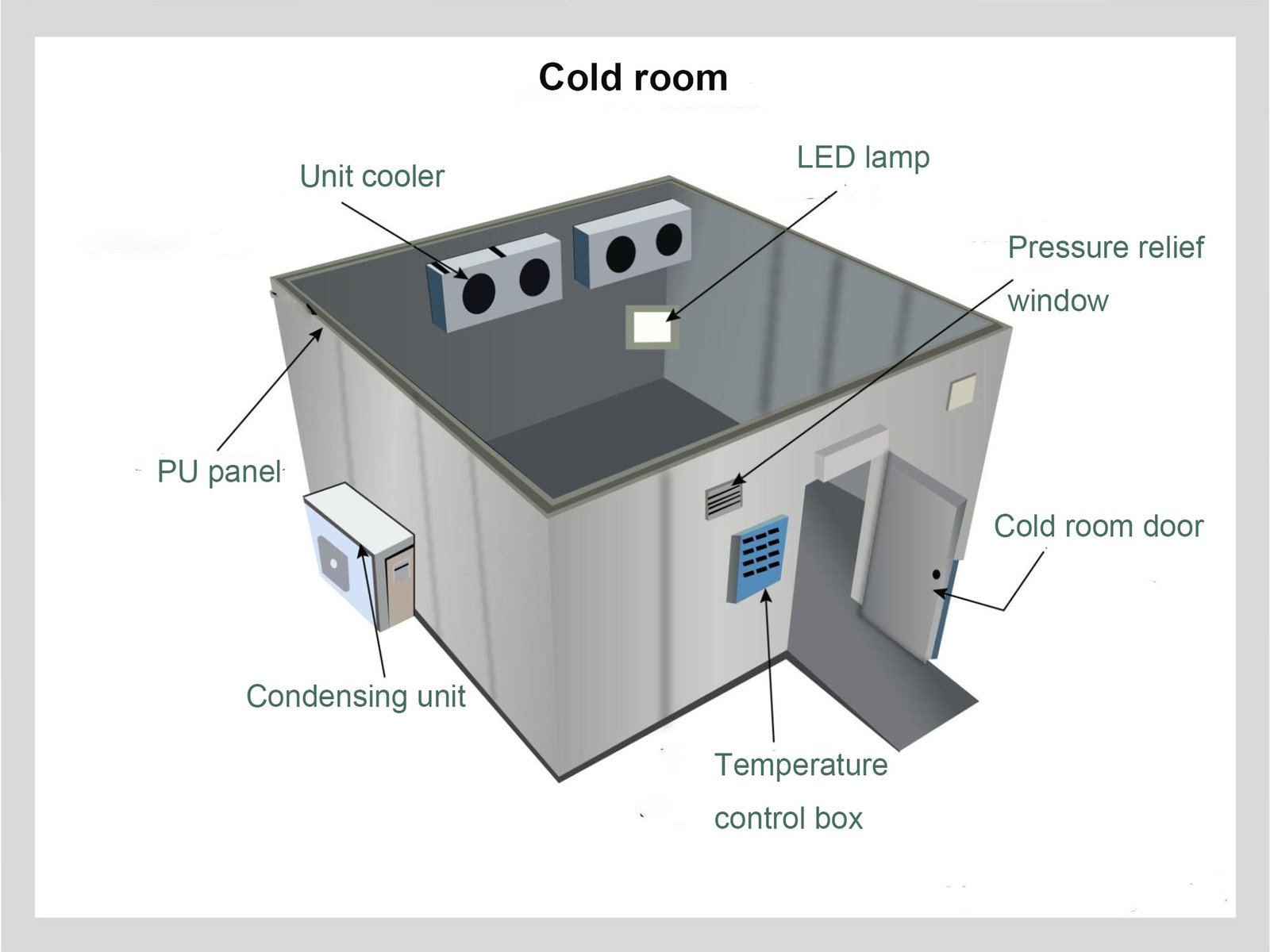

- High-Performance Insulation: Panels with polyurethane foam cores and a high R-value (above R-34 for 100mm thickness is now common) are standard for premium builds. Better insulation means smaller, less expensive refrigeration units.

- Heat Recovery Systems: This is a premium feature. The heat extracted from the cold room can be used to pre-heat water for sanitation, a huge selling point for hotels, dairies, or food processors looking to slash utility bills.

| Industry Application | Critical Temp. Range | Key Feature Focus | Primary Concern |

|---|---|---|---|

| Fresh Produce Distribution | 0°C to 4°C (32°F to 39°F) | High Humidity Control (90-95%), Ethylene Scrubbers | Moisture Loss, Premature Ripening |

| Pharmaceutical Storage | +2°C to +8°C (36°F to 46°F) | Audit Trail Data Loggers, Alarm Redundancy, Battery Backup | Regulatory Compliance, Product Efficacy |

| Frozen Foods Warehouse | -18°C to -25°C (-0.4°F to -13°F) | Rapid Pulldown Capacity, Robust Floor Freeze Protection | Temperature Stability, Energy Cost |

| Restaurant Central Kitchen | 0°C to 3°C (32°F to 37°F) | Heavy-Duty Shelving, Easy-Clean Surfaces, Traffic Flow Design | Cross-Contamination, Workflow Efficiency |

| Floral Cold Storage | 1°C to 4°C (34°F to 39°F) | Dark Environment, Specific Spectrum Lighting, Very High Humidity | Petal Desiccation, Ethylene Sensitivity |

Pre-Installation Checklist: Avoiding Costly Call-Backs

A great installation prevents 90% of future problems. Advise your dealers to get this right on day one.

- Site, Site, Site: Verify the floor is perfectly level. An unlevel floor causes door misalignment and seal failure. Ensure there’s adequate space for condenser airflow—crowding it against a wall is a recipe for overheating and failure.

- Electrical Reality Check: Don’t assume. Verify the voltage, phase, and amperage at the site match the unit’s requirements. A dedicated circuit is almost always necessary.

- Future-Proofing: Discuss potential business growth. Is adding a second cold room later a possibility? Leave space and plan electrical capacity accordingly. Recommending modular panels shows you’re thinking long-term.

Your Professional Q&A Corner

Q: What’s the current trend in refrigerants, and how does it affect my clients?

A: The global shift is towards lower GWP (Global Warming Potential) refrigerants like R-448A, R-449A, and natural options like CO2 (R-744) and Ammonia (R-717). For most commercial walk-ins, HFO blends like R-448A are becoming the new standard, offering similar performance to older HFCs like R-404A but with a 65% lower GWP. This future-proofs your client’s investment against tightening environmental regulations.

Q: How long should a well-maintained walk-in cold room last?

A: With proper installation, routine professional maintenance, and timely component replacement (like gaskets and fan motors), the structural shell (panels) should last 20-30 years. The refrigeration unit itself typically has a lifespan of 10-15 years. Proactive maintenance is the single biggest factor in maximizing lifespan and ROI.

Q: What’s the #1 mistake you see in cold room operations that wastes energy?

A: Leaving the door open during loading/unloading is a major one, but an even more insidious mistake is setting the temperature lower than necessary. Each degree Celsius below required adds approximately 2-4% to the energy bill. Precise setpoints and disciplined door discipline are the easiest wins for energy savings.

Q: Can a cold room be too efficient for products like fresh meat or cheese that require aging?

A: Absolutely. This is where precise humidity control is critical. Many artisanal products require specific, often high, humidity levels to prevent surface drying while allowing natural processes to occur. A “one-setting-fits-all” approach can ruin product quality. The equipment must allow for independent control of temperature and humidity.