Beyond the Basics: How Air-Cooled Condensing Units Power Diverse Industries

So, you’re in the business of sourcing or supplying commercial and industrial cooling equipment. You’ve heard the term “air-cooled condensing unit” a thousand times. But when a client from a bakery, a data center, or a pharmaceutical plant asks, “Is this the right chill solution for us?” – you need more than just a textbook definition. You need the real, operational know-how that turns specs into solutions. Let’s break down exactly what these workhorses are and why they’re the silent backbone of so many sectors.

H2: The Core Anatomy – More Than Just a Fan and a Coil

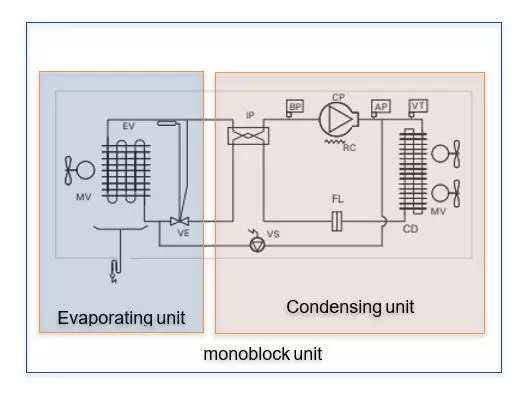

At its heart, an air-cooled condensing unit is a self-contained refrigeration system designed to reject heat from an interior space or process to the outside atmosphere. Unlike water-cooled systems that need a cooling tower and a constant water supply, this unit uses ambient air as its cooling medium. Here’s what’s inside the cabinet:

- Compressor: The pump of the system. It takes low-pressure, low-temperature refrigerant gas from the evaporator and squeezes it into a high-pressure, high-temperature gas. Scroll compressors dominate the market for their reliability and efficiency in mid-range capacities, while screw compressors take over for larger industrial needs.

- Condenser Coil: A network of copper or aluminum tubes with aluminum fins. The hot refrigerant gas flows through here.

- Condenser Fans: High-static-pressure fans (usually axial) that pull or push ambient air across the condenser coil. This air absorbs the heat from the refrigerant, causing it to condense into a high-pressure liquid.

- Electrical Control Panel: Houses the contactors, starters, capacitors, and the modern brain – the microprocessor controller. Top-tier units now feature IoT-enabled controls for remote monitoring.

- Receiver (Optional but common): A storage tank for liquid refrigerant, ensuring a stable supply to the expansion device under varying loads.

The magic is in the synergy. The compressor pushes, the fans blow, the coil transfers, and heat is ejected. Simple in principle, but the engineering depth is what you pay for.

H2: The Tech Evolution – What Smart Buyers Look For Now

The market isn’t buying the same units it did five years ago. Driven by global energy regulations and TCO (Total Cost of Ownership) demands, the technology has leaped forward. Here’s the current landscape:

- Variable Speed Drive (VSD/VFD) Domination: It’s no longer a premium feature but a standard expectation for efficiency. A VSD on the compressor and fans allows the unit to precisely match its output to the exact cooling demand, slashing energy consumption by 30-50% compared to fixed-speed units. For a distributor, this is your key selling point against cheaper, obsolete models.

- EC (Electronically Commutated) Fans: These are the new norm for fan motors. They offer superior efficiency, precise speed control linked to head pressure, and are significantly quieter – a critical factor for urban installations.

- R-454B & R-32 Refrigerants: The phasedown of HFCs like R-410A is real. Leading manufacturers are now shipping units with lower-GWP (Global Warming Potential) refrigerants. R-454B has about 78% lower GWP than R-410A and is becoming the mainstream successor. Your clients in Europe and North America are already facing regulatory pressure on this front.

- Connected Intelligence: Modern units come with built-in connectivity (Modbus, BACnet, Ethernet) and can be part of a cloud-based monitoring system. A distributor can offer added value by providing platforms that allow end-users to track performance, receive preventive maintenance alerts, and optimize schedules remotely.

Here’s a snapshot of the efficiency shift, based on current manufacturer data for a nominal 100kW cooling capacity unit:

| Feature | Standard Fixed-Speed Unit (5 years ago) | Modern VSD/EC Fan Optimized Unit (Current) | Impact for B2B Buyer |

|---|---|---|---|

| Compressor Type | Fixed-Speed Scroll | VSD Scroll or Screw | Precise load matching, massive energy savings. |

| Fan Motor Type | PSC (Permanent Split Capacitor) | EC (Electronically Commutated) | Lower power draw, quieter operation, better control. |

| Seasonal Efficiency | SEER 13 / IEER 12 | SEER 18+ / IEER 16+ | Directly lower operational costs for end-client. |

| Standard Refrigerant | R-410A (GWP 2088) | R-454B (GWP 466) or R-32 (GWP 675) | Future-proof against environmental regulations. |

| Control System | Basic thermostat | Microprocessor with IoT readiness | Enables predictive maintenance and data services. |

H2: Cross-Industry Application – The Versatility Play

This is where your knowledge as a distributor becomes critical. Understanding these applications lets you match the right unit features to the client’s pain point.

- Commercial HVAC & Retail: Supermarkets, malls, office buildings. Here, multiple smaller units (rooftop modular units) offer redundancy and zoning. Key needs are low noise (for urban settings), high energy efficiency (to manage utility bills), and ease of service. The trend is towards distributed systems over single, massive central plants.

- Food & Beverage Processing: From blast chilling in meat plants to fermentation control in breweries. Hygienic design (coated coils, stainless steel cabinets), corrosion resistance, and the ability to operate reliably in harsh, hot, and wet environments are paramount. Capacity must handle high peak loads.

- Pharmaceutical & Laboratories: Precision is everything. Units support process cooling for reactors and climate control for cleanrooms. Stability, precise temperature control (±0.5°C), and redundancy are non-negotiable. Units often run year-round, so part-load efficiency is crucial.

- Data Centers & Telecom Shelters: The heat density is immense. The units work in N+1 redundant configurations for 99.999% uptime. They must integrate with broader Building Management Systems (BMS) and often feature dual circuits – if one circuit fails, the other maintains partial cooling.

- Industrial Process Cooling: For plastic injection molding, laser cutting, chemical processes. These units are built like tanks. They prioritize robust components, high ambient operation (up to 52°C/125°F), and often use glycol solutions as secondary coolant, requiring specific heat exchanger designs.

H2: Sourcing Smart – Key Specs Beyond the Price Tag

When evaluating units from a manufacturer (like us), you need a checklist that looks beyond the catalog sticker price. This is your due diligence for long-term customer satisfaction.

- Design Ambients: Where will this unit operate? A unit rated for a max 35°C ambient will fail in a Middle Eastern summer where 48°C is common. Ensure the specs match the regional climate.

- Sound Pressure Levels: Measured in dB(A). Lower is better, especially for installations near residential areas. Check if the quoted sound level is for the full unit or just the fan.

- Electrical Specifications: Voltage, phase, frequency (50Hz/60Hz). A truly global manufacturer offers dual-frequency motors and a range of voltages. This simplifies your inventory for different export markets.

- Corrosion Protection: For coastal or industrial areas, ask about specific treatments – epoxy-coated coils, aluminum or stainless steel casings, galvanized frames. A standard unit will corrode in months near saltwater.

- Serviceability: Can a technician easily access the compressor, filters, and electrical panel? Are service ports standard? Good design minimizes downtime.

- Manufacturer’s Testing & Certification: Look for units tested under AHRI (Air-Conditioning, Heating, and Refrigeration Institute) conditions. Certifications like CE, UL, and CRAA are passports for different markets.

The goal is to source a unit that won’t lead to costly callbacks. A slightly higher unit cost with robust features saves immense hassle and protects your brand reputation.

Professional Q&A for the B2B Distributor

Q: Our client is concerned about rising energy costs. What’s the single biggest feature we should steer them towards?

A: Without a doubt, Variable Speed Drive (VSD) on the compressor. While EC fans add savings, the compressor is the largest energy consumer. A VSD allows the unit to “ramp down” during milder conditions, avoiding the energy spikes of constant on/off cycling. The ROI on the premium for a VSD unit is often under 2 years in high-use applications.

Q: With the refrigerant transition, is it risky to stock units with R-410A?

A: For most developed markets, yes, it’s becoming a liability. Regulations like the EU F-Gas Regulation and the US AIM Act are actively phasing down HFCs. Selling an R-410A unit today could mean your end-client faces difficulty servicing it or sourcing refrigerant in 5-7 years. Future-proof your inventory by prioritizing models with R-454B or other approved lower-GWP alternatives. It’s a easier sell when you frame it as regulatory risk mitigation.

Q: How critical is remote monitoring for our commercial clients?

A: It’s shifting from a “nice-to-have” to a “must-have” for proactive facilities management. For you as a distributor, it opens a service revenue stream. For the client, it prevents catastrophic failure. An alert for a dropping refrigerant pressure or a rising condenser temperature can trigger a service call before a system shuts down, avoiding spoilage in a supermarket or downtime in a factory. It transforms your relationship from transactional to partnership-based.

Q: We have a project in a high-ambient, dusty environment. What specific upgrades should we quote?

A: This requires a hardened specification. Key upgrades include: 1) High-Ambient Components: Compressor and motors rated for continuous operation at the extreme local temperature (e.g., 52°C). 2) Enhanced Filtration: Heavy-duty, easy-clean air filters on the condenser coil intake. 3) Corrosion Protection: An upgraded coil coating (like hydrophilic epoxy) and a cabinet with a higher-quality finish. 4) Condenser Fan Guards: To protect blades from debris. Never ship a standard unit for such conditions; it will lead to premature failure and an unhappy customer.