Are you tired of one-size-fits-all cold storage solutions that fail to meet your industry’s unique needs? 🤔 In today’s fast-paced world of food preservation, pharmaceutical storage, and logistics management, generic cold rooms simply don’t cut it anymore. Custom cold room solutions are revolutionizing how businesses handle temperature-sensitive products, offering tailored approaches that maximize efficiency and ensure product integrity.

Imagine a world where your perishables stay fresher for longer, your pharmaceuticals maintain perfect potency, and your logistics operations run like a well-oiled machine. 🍎💊📦 This isn’t just a dream – it’s the reality that custom cold room solutions are bringing to industries across the board. From precise temperature control to energy-efficient designs, these bespoke storage environments are changing the game for businesses big and small.

In this comprehensive guide, we’ll dive deep into the world of custom cold room solutions, exploring their applications in food, pharma, and logistics industries. We’ll uncover the key features that make modern cold rooms stand out, help you select the perfect solution for your needs, and even peek into the future of cold storage technology. Get ready to discover how customized cold rooms can transform your operations and give you the edge in today’s competitive market!

Understanding Custom Cold Room Solutions

Defining custom cold rooms

Custom cold rooms are specialized temperature-controlled environments designed to meet specific storage and preservation requirements. These versatile solutions are tailored to maintain precise temperature and humidity levels, ensuring optimal conditions for various products and industries.

Key components of cold room systems

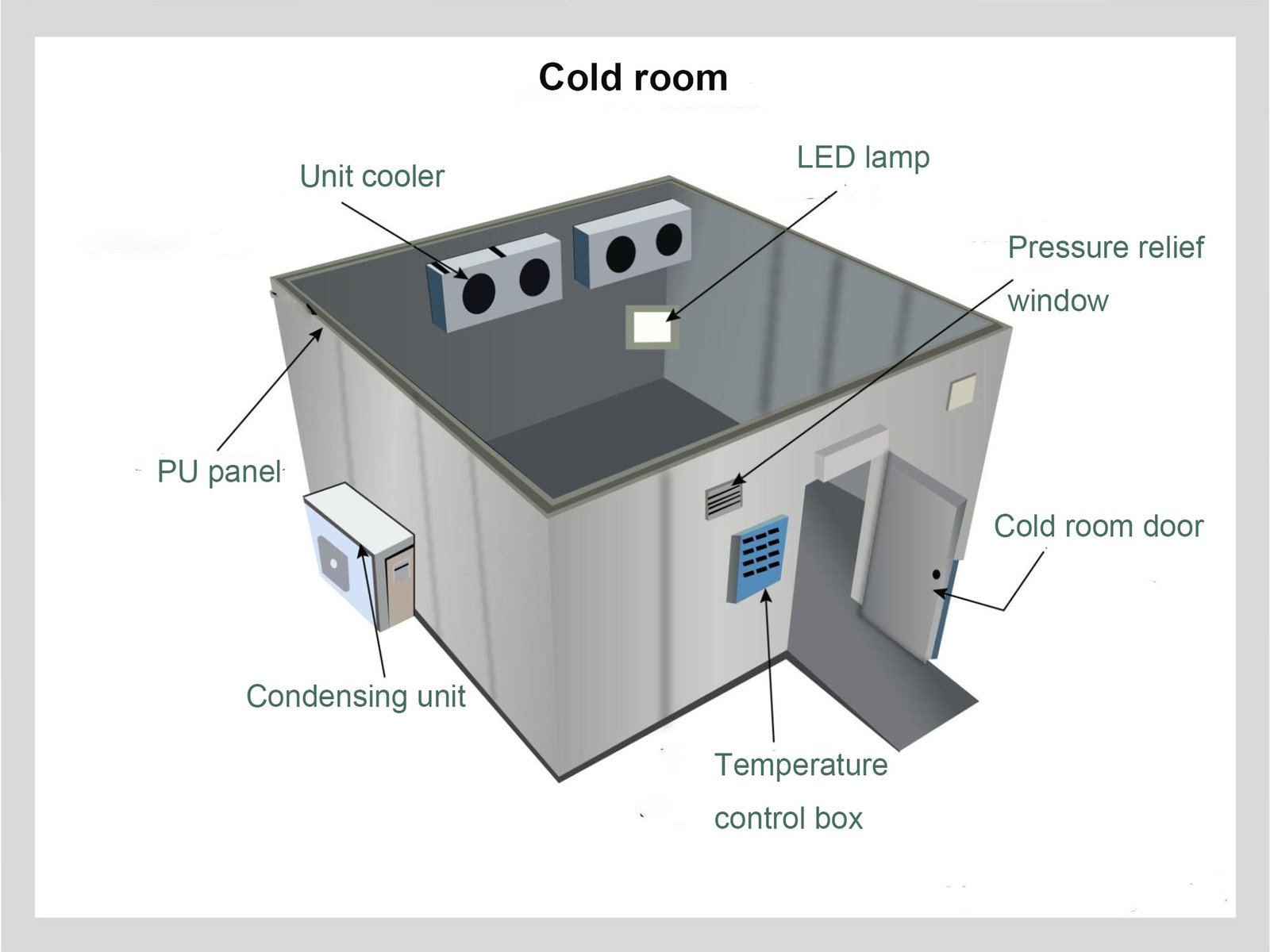

Cold room systems comprise several essential components working in harmony to maintain the desired environment:

- Insulation panels

- Refrigeration units

- Temperature control systems

- Ventilation and air circulation

- Doors and seals

| Component | Function |

|---|---|

| Insulation panels | Maintain temperature by minimizing heat transfer |

| Refrigeration units | Cool the air to desired temperature |

| Temperature control systems | Monitor and regulate temperature |

| Ventilation and air circulation | Ensure uniform temperature distribution |

| Doors and seals | Prevent air leakage and maintain insulation |

Importance of tailored solutions

Customized cold room solutions offer numerous benefits:

- Improved energy efficiency

- Enhanced product quality and shelf life

- Compliance with industry-specific regulations

- Optimized space utilization

- Reduced operational costs

By tailoring cold rooms to specific needs, businesses can ensure optimal performance, longevity, and return on investment. This personalized approach allows for the integration of advanced features and technologies that address unique challenges in various industries, from food preservation to pharmaceutical storage and logistics operations.

Cold Room Applications in the Food Industry

Preserving perishable goods

Custom cold rooms play a crucial role in preserving perishable goods in the food industry. These specialized storage solutions maintain optimal temperature and humidity levels, ensuring that fresh produce, dairy products, and meats retain their quality and nutritional value.

- Benefits of custom cold rooms for food preservation:

- Temperature control

- Humidity regulation

- Air circulation management

- Contamination prevention

| Food Type | Ideal Temperature Range | Relative Humidity |

|---|---|---|

| Fruits | 32°F – 40°F (0°C – 4°C) | 85% – 95% |

| Vegetables | 32°F – 55°F (0°C – 13°C) | 85% – 95% |

| Dairy | 33°F – 38°F (0.5°C – 3°C) | 65% – 70% |

| Meat | 28°F – 32°F (-2°C – 0°C) | 85% – 90% |

Meeting regulatory requirements

Custom cold rooms are designed to meet strict regulatory standards set by food safety authorities. These solutions incorporate features that ensure compliance with HACCP (Hazard Analysis and Critical Control Points) guidelines and other industry-specific regulations.

Enhancing food safety

Cold rooms contribute significantly to food safety by:

- Preventing bacterial growth

- Reducing the risk of cross-contamination

- Maintaining proper segregation of different food types

- Facilitating easy cleaning and sanitization

Extending shelf life

By providing a controlled environment, custom cold rooms effectively extend the shelf life of various food products. This extension not only reduces waste but also allows for better inventory management and increased profitability for food businesses.

Now that we’ve explored the applications of cold rooms in the food industry, let’s examine how these solutions are tailored for the unique needs of the pharmaceutical sector.

Pharmaceutical Cold Storage Solutions

Temperature-sensitive medication storage

Pharmaceutical cold storage solutions are crucial for maintaining the efficacy and safety of temperature-sensitive medications. These specialized storage units must maintain precise temperature ranges to ensure drug stability. Here’s a breakdown of common temperature requirements:

| Temperature Range | Example Medications |

|---|---|

| 2°C to 8°C | Vaccines, insulin |

| -20°C to -10°C | Certain biologics |

| Below -60°C | Gene therapies |

Proper storage involves:

- Continuous temperature monitoring

- Backup power systems

- Alarm systems for temperature deviations

- Restricted access controls

Compliance with Good Manufacturing Practices (GMP)

Adhering to GMP guidelines is essential for pharmaceutical cold storage. Key compliance aspects include:

- Documentation of temperature logs

- Regular calibration of monitoring equipment

- Implementation of quality management systems

- Staff training on proper handling procedures

Maintaining product efficacy

To preserve medication potency, cold rooms must:

- Minimize temperature fluctuations

- Control humidity levels

- Protect from light exposure

- Ensure proper air circulation

Specialized vaccine storage solutions

Vaccine storage demands unique considerations:

- Ultra-low temperature freezers for mRNA vaccines

- Portable cold chain equipment for distribution

- Real-time tracking systems for temperature-sensitive shipments

These solutions are critical for maintaining vaccine integrity from manufacture to administration, ensuring public health initiatives’ success.

Optimizing Logistics with Custom Cold Rooms

Cold chain management

Cold chain management is crucial for maintaining product quality and safety throughout the logistics process. Custom cold rooms play a vital role in this by providing:

- Temperature-controlled environments

- Real-time monitoring systems

- Humidity control

- Air circulation management

| Feature | Benefit |

|---|---|

| Temperature control | Prevents product spoilage |

| Real-time monitoring | Ensures compliance and quick response |

| Humidity regulation | Maintains product integrity |

| Air circulation | Promotes uniform cooling |

Reducing product loss during transportation

Custom cold rooms significantly reduce product loss during transportation by:

- Maintaining consistent temperatures

- Providing shock absorption features

- Utilizing advanced insulation materials

- Implementing backup power systems

These features ensure that products remain in optimal condition from origin to destination, minimizing waste and maximizing profits.

Streamlining warehouse operations

Custom cold rooms enhance warehouse efficiency by:

- Optimizing space utilization

- Facilitating quick loading and unloading

- Integrating with inventory management systems

- Allowing for modular expansion

Enhancing inventory control

Improved inventory control is achieved through:

- RFID technology integration

- Automated stock rotation systems

- Real-time inventory tracking

- Temperature-specific zoning

These advancements enable businesses to maintain accurate stock levels, reduce overstock situations, and ensure first-in-first-out (FIFO) practices. With enhanced inventory control, companies can optimize their supply chain, reduce costs, and improve overall operational efficiency.

Key Features of Modern Cold Room Solutions

Energy-efficient designs

Modern cold room solutions prioritize energy efficiency to reduce operational costs and environmental impact. Key features include:

- High-performance insulation materials

- LED lighting systems with motion sensors

- Variable speed compressors

- Energy recovery ventilation systems

These design elements work together to minimize energy consumption while maintaining optimal temperature control.

Advanced temperature monitoring systems

State-of-the-art monitoring systems ensure precise temperature regulation:

- Wireless sensors for real-time temperature tracking

- Cloud-based data logging and analysis

- Automated alerts for temperature fluctuations

- Integration with building management systems

| Feature | Benefit |

|---|---|

| Real-time tracking | Immediate response to temperature changes |

| Cloud-based logging | Easy access to historical data |

| Automated alerts | Rapid issue resolution |

| BMS integration | Centralized facility management |

Customizable storage configurations

Flexible storage options cater to diverse product requirements:

- Adjustable shelving systems

- Modular racking solutions

- Temperature-zoned compartments

- Specialized storage for sensitive items

Integration with existing infrastructure

Seamless integration capabilities ensure smooth operations:

- Compatible with various building structures

- Adaptable to existing HVAC systems

- Scalable designs for future expansion

- Compliance with industry-specific regulations

Remote management capabilities

Advanced remote management features enhance operational efficiency:

- Mobile apps for monitoring and control

- Remote diagnostics and troubleshooting

- Predictive maintenance algorithms

- Multi-site management platforms

These key features of modern cold room solutions offer businesses enhanced control, efficiency, and reliability in their cold storage operations. Next, we’ll explore how to select the right cold room solution for your specific needs.

Selecting the Right Cold Room Solution

Assessing specific industry needs

When selecting a custom cold room solution, it’s crucial to thoroughly assess your industry-specific requirements. Different sectors have unique needs:

| Industry | Key Considerations |

|---|---|

| Food | Temperature zones, humidity control, food safety regulations |

| Pharmaceuticals | Precise temperature control, security features, compliance with GMP |

| Logistics | Size flexibility, rapid cooling, energy efficiency |

Start by analyzing your product types, storage volumes, and temperature ranges. Consider any regulatory compliance requirements specific to your industry.

Considering scalability and future growth

A well-designed cold room should accommodate your business’s future needs:

- Modular designs for easy expansion

- Flexible layout options

- Upgradable cooling systems

Plan for at least 20-30% additional capacity to handle potential growth or seasonal fluctuations in demand.

Evaluating cost-effectiveness

While upfront costs are important, focus on the total cost of ownership:

- Initial investment

- Energy efficiency ratings

- Maintenance costs

- Potential energy-saving features (e.g., LED lighting, advanced insulation)

Consider options like thermal energy storage systems, which can significantly reduce operating costs over time.

Analyzing maintenance requirements

Regular maintenance is crucial for optimal cold room performance:

- Choose solutions with easily accessible components

- Look for systems with remote monitoring capabilities

- Consider the availability of local service technicians

Opt for cold rooms with self-diagnostic features and predictive maintenance technologies to minimize downtime and extend equipment lifespan.

With these factors in mind, let’s explore the emerging trends shaping the future of cold room technology.

Emerging Trends in Cold Room Technology

IoT integration for real-time monitoring

In the rapidly evolving world of cold room technology, IoT integration has emerged as a game-changer. This advancement allows for real-time monitoring of critical parameters, ensuring optimal storage conditions and reducing the risk of product spoilage.

Key benefits of IoT integration in cold rooms include:

- Continuous temperature tracking

- Humidity level monitoring

- Energy consumption analysis

- Automated alerts for anomalies

| Feature | Benefit |

|---|---|

| Remote access | Monitor conditions from anywhere |

| Data logging | Historical analysis for compliance |

| Predictive analytics | Identify potential issues before they occur |

| Integration with ERP systems | Streamline inventory management |

Sustainable refrigeration systems

As environmental concerns take center stage, the cold room industry is shifting towards more sustainable refrigeration solutions. These eco-friendly systems not only reduce carbon footprint but also offer long-term cost savings.

AI-powered predictive maintenance

Artificial Intelligence is revolutionizing cold room maintenance practices. By analyzing vast amounts of data, AI algorithms can predict potential equipment failures before they occur, minimizing downtime and extending the lifespan of cold room components.

Modular and portable cold room designs

The demand for flexible storage solutions has led to the development of modular and portable cold rooms. These innovative designs offer:

- Quick installation and relocation

- Scalability to meet changing storage needs

- Reduced construction costs

- Adaptability for temporary or seasonal use

These emerging trends are shaping the future of cold room technology, offering enhanced efficiency, sustainability, and flexibility across various industries.

Custom cold room solutions have become indispensable across various industries, offering tailored storage environments for food, pharmaceuticals, and logistics. From preserving perishable goods to maintaining the efficacy of sensitive medications, these specialized facilities play a crucial role in ensuring product quality and safety. The versatility of modern cold rooms, coupled with advanced features like remote monitoring and energy-efficient designs, provides businesses with the flexibility to meet diverse storage requirements while optimizing operational costs.

As technology continues to evolve, the future of cold room solutions looks promising. With emerging trends such as AI-driven temperature control and sustainable refrigeration systems, businesses can expect even more efficient and environmentally friendly options. When selecting a custom cold room solution, it’s essential to consider factors such as capacity, temperature range, and industry-specific regulations to ensure the chosen system aligns with your unique needs and compliance requirements. By investing in the right cold room solution, businesses can enhance their operational efficiency, maintain product integrity, and stay ahead in today’s competitive market.