The Heartbeat of Cooling Systems: AC Condenser Fan Motors Across Industries

So, you’re sourcing components, maybe building units, or supplying parts for massive projects. You’ve heard the term “condenser fan motor” a hundred times. It sounds like a small piece in a vast puzzle. But in the world of thermal management, this component isn’t just a part; it’s the critical pulse that determines whether a system lives up to its specs or falls flat. Let’s strip away the jargon and talk about what it really is, why its specs matter to your bottom line, and how it plays out in different fields you deal with every day.

The Core Mechanics: More Than Just Spinning Blades

At its simplest, an AC unit condenser fan motor is a workhorse electric motor specifically designed to drive the fan blades sitting atop a condenser coil. Its job is non-negotiable: pull ambient air through that coil. Here’s the straightforward physics—inside the coil, a hot, high-pressure refrigerant gas needs to shed its heat. The fan motor forces air across the coil’s fins, facilitating rapid heat transfer. The refrigerant condenses into a liquid, releasing that harvested heat from indoors to the outdoors. No efficient airflow equals failed heat rejection, which means the compressor works harder, pressure skyrockets, efficiency plummets, and the system trips on safety controls.

For you as a B2B decision-maker, the motor is defined by a set of tangible, orderable specs. It’s not a commodity. We’re talking about specific horsepower (HP) ratings, rotational speeds (RPM), shaft dimensions, mounting footprints, voltage requirements (115V, 230V, 460V, etc.), and crucially, the protection format. Is it an open drip-proof (ODP) motor for general use, or a totally enclosed air-over (TEAO) motor built to withstand harsh weather and debris? The choice directly impacts warranty claims, system longevity, and your client’s satisfaction.

Demand Drivers: From Data Centers to Supermarket Aisles

The performance requirements for this motor shift dramatically based on the application. This isn’t one-size-fits-all; it’s a precision-matched component.

Commercial HVAC & Office Complexes: Here, reliability and noise levels are king. Motors need to run continuously for thousands of hours with minimal vibration. The trend is sharply moving towards Electronically Commutated Motors (ECMs). Why? For you, it’s a value-add. ECMs offer variable speed control, which aligns with building automation systems (BAS), leading to significant energy savings—a major selling point for your clients. Their higher initial cost is offset by operational savings and compliance with tightening global energy codes like Eurovent and AHRI standards.

Industrial Process Cooling & Manufacturing: This is the brutal environment. Motors cool condensers for chillers that control processes in plastics molding, pharmaceutical production, or food processing. They battle corrosive fumes, conductive dust, and extreme ambient temperatures. Here, robustness is the only spec. We’re talking heavy-duty, corrosion-resistant TEAO motors with high starting torque. Downtime in these applications costs thousands per minute, so the motor’s mean time between failure (MTBF) rating isn’t a line item; it’s an insurance policy.

Cold Chain & Refrigerated Storage: Walk into a warehouse freezer or a supermarket cold room. The condenser unit is often on the roof, and its fan motor is operating in winter conditions. It must be engineered for low-ambient start-up. Standard motors can struggle. Additionally, for food safety, systems often run 24/7/365. The motor’s bearing life, lubrication quality, and insulation class (like Class F for higher temperature tolerance) become critical procurement criteria for your buyers who cannot afford a spoilage event.

- Data Center Cooling: The pinnacle of precision. Data center cooling units (CRACs/CRAHs) demand fault tolerance. Redundancy is often designed in, but each motor must be hyper-efficient and reliable. The focus is on maximizing airflow at the lowest possible wattage. ECMs dominate here. For 2024, the conversation with your tech-savvy clients will center on specific efficiency metrics, compatibility with DCIM (Data Center Infrastructure Management) software, and acoustic performance, as data centers move closer to populated areas.

2024 Procurement Lens: Specifications That Seal the Deal

Gone are the days of just matching HP and voltage. Your clients are now asking for data. Here’s what matters in current RFQs:

| Specification | Why It Matters for Your B2B Transaction | Industry Benchmark Trend (2024) |

|---|---|---|

| Motor Efficiency | Directly impacts end-user operational cost. Higher efficiency = a stronger value proposition. | IE3 (Premium Efficiency) is now table stakes. IE4 (Super Premium) demand is rising in EU/APAC. |

| Speed Control | Fixed vs. Variable Speed. Variable (ECM) enables smart control, dehumidification, and energy savings. | ECM adoption growing >15% YOY in commercial sectors. A key upgrade upsell. |

| Protection Rating | IP (Ingress Protection) rating defines defense against solids/liquids. IP54 or higher is standard for outdoor. | IP55 for general outdoor; IP56 for coastal/harsh industrial sites. |

| Material & Build | Body: Aluminum (light, corrosion-resistant) vs. Cast Iron (durable, dissipates heat better). | Aluminum dominates for weight/cost; Cast Iron preferred for high-heat, long-cycle industrial duty. |

| Noise Level (dBA) | Critical for urban installations, schools, hospitals. Lower dBA = easier permitting and happier end-customers. | Sub-65 dBA at 1 meter is a common market requirement for residential/commercial units. |

| Smart Readiness | Compatibility with BACnet, Modbus, or proprietary protocols for system integration. | Moving from a “nice-to-have” to a standard request in commercial/industrial projects. |

When you’re evaluating a supplier, don’t just look at the unit price. Audit the testing certificates (e.g., from UL, CE, or CCC), ask for the full load amp (FLA) data, and understand the warranty terms. A motor with a 5-year warranty from a manufacturer that performs 100% load testing is a lower-risk inventory item for your business than an untested unit with a 1-year warranty.

Installation Realities and Longevity Factors

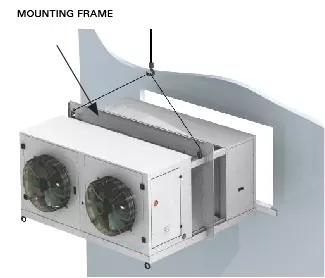

You know your clients will face installation challenges. The right motor minimizes them. Shaft alignment is paramount. A misaligned coupling or set screw creates vibration that kills bearings and prematurely ages the entire condenser assembly. Thermal overload protection is another non-negotiable. A motor with an internal auto-reset overload protects itself and the system during voltage spikes or blockage events.

Preventative maintenance is your aftermarket opportunity. Educate your buyers: the leading cause of premature motor failure is dirt accumulation. It insulates the motor, causing it to overheat. A simple quarterly visual inspection for debris and an annual check of bearing play and electrical connections can triple a motor’s service life. Stocking and offering installation-ready retrofit kits—motor, fan blade, mounting hardware—is a high-value service for your B2B customers.

Navigating the Global Supply Chain

As an importer/exporter, you’re navigating lead times, tariffs, and logistics. In 2024, dual-sourcing for critical components like these is a common strategy. You might source a standard efficiency, cast-iron motor from a reliable regional manufacturer for quick-turn projects and a high-efficiency ECM line from a specialized global partner for premium bids. Understanding the country-of-origin impact on tariffs (like Section 301 in the U.S.) and having clear documentation on component origin is now part of the professional sourcing playbook.

The conversation is also shifting towards sustainability. Clients in the EU and North America are increasingly asking for motors that are RoHS compliant and built with recyclable materials. It’s a specification that’s moving from the environmental, social, and governance (ESG) report into the purchase order.

Professional Q&A

Q: Our client’s condenser fan motor fails every 1-2 years in a coastal application. What should we recommend?

A: This is classic corrosion failure. Immediately stop supplying standard ODP motors. Switch to a TEAO (Totally Enclosed Air-Over) motor with a corrosion-resistant coating, such as an epoxy or marine-grade finish. Ensure the motor has a minimum IP56 rating to protect against salt-laden moisture and driven rain. The upfront cost is higher, but it will solve the chronic failure issue.

Q: We are bidding on a project in the EU that requires compliance with Ecodesign regulations. What motor efficiency class do we need?

A: For most AC fan motors above 0.12 kW, the EU Ecodesign Regulation (EU) 2019/1781 mandates a minimum IE3 efficiency level as of July 1, 2021. For higher-value projects or those aiming for green building certifications, specify IE4 motors. Always request and file the official EU Declaration of Conformity from your motor supplier for the products shipped to this project.

Q: A customer wants to upgrade an old fixed-speed unit to a variable speed system. Can we just swap in an ECM motor?

A: Not directly. An ECM requires a compatible controller or control board that provides the low-voltage DC signal and logic for variable speed operation. You must verify if the existing system’s board has this capability or if an aftermarket controller kit is available. The upgrade often involves replacing the motor and the control system. Sell it as a complete retrofit kit to ensure functionality.

Q: What’s the single most important electrical specification to check when cross-referencing a replacement motor?

A: The Full Load Amps (FLA). Never just match horsepower. A motor with the correct HP but a lower FLA than the original may be underpowered and overheat. A motor with a significantly higher FLA can overload the circuit protection (fuse, breaker) and the existing wiring. Always match or slightly exceed the FLA, and ensure the voltage (e.g., 208-230V) and phase (1 or 3) are identical.